See why the world trusts Minitab for quality at.

#Minitab process capability how to

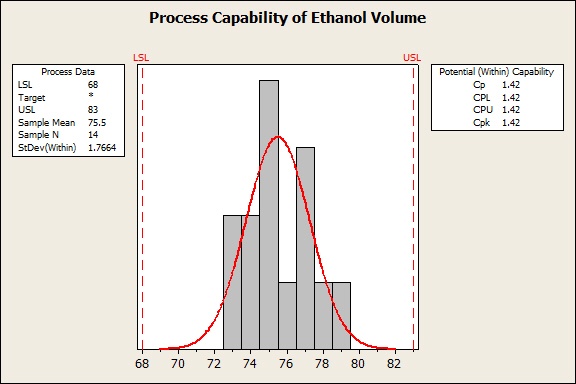

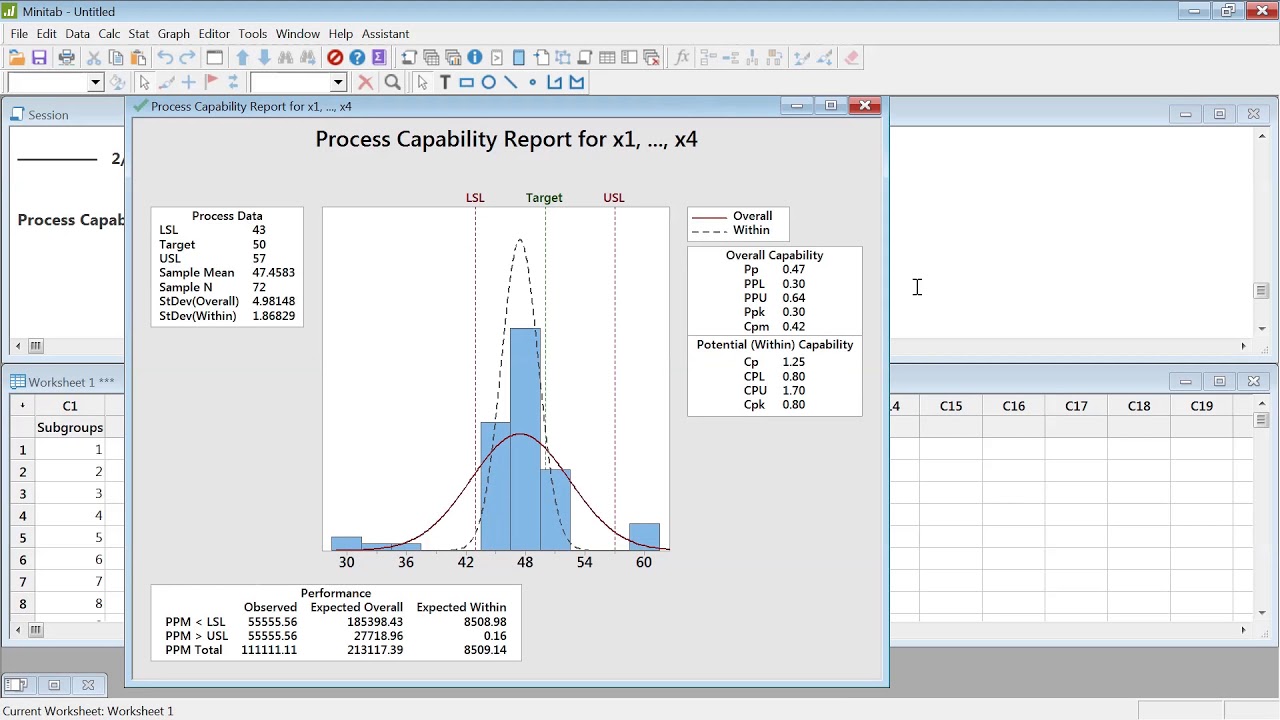

Detailed Interpretation of results in Graph Window including Xbar and R-Chart, the Last 20 subgroups plot, Normal Probability Plot, Capability Histogram and Capability plot with Cpk, Ppk and Cpm values, how to interpret Capability Sixpack graph and Conclusion. Control Charts and Capability Analysis: How to Set Up Your Data. Minitab is the world's leading statistical software for Six Sigma and statistics education.The detailed stepwise procedure with a screenshot to understand how to conduct Normal Capability Sixpack in Minitab.Normal Capability Sixpack with Practical Example in Minitab.Data considerations for Normal Capability Sixpack.Introduction to Normal Capability Sixpack.This video consists of the following topics: The differences in other types are only the distribution of data or extent of variation in subgroups, same as that of seen in the previous videos on “Between/Within Capability analysis” and “Nonnormal Capability analysis”. Each member of the team needs to collect samples to prepare 10 samples from two. “Normal Capability Sixpack” in this video. Use Minitab for prepare Conduct a Process Capability Ratio analysis. In Capability Sixpack, there are 3 types of analysis:Īs the procedure to conduct this analysis and interpretations of them are the same, we will learn only 1st type of it i.e. In this video, we are going to learn advance concepts or tools in capability analysis for continuous data i.e.

#Minitab process capability series

We are going to learn Process Capability, one of the most important tools in Six Sigma, in a series of videos from this video onward.

0 kommentar(er)

0 kommentar(er)